Conference opening + Introductions

09h00 – 09h30

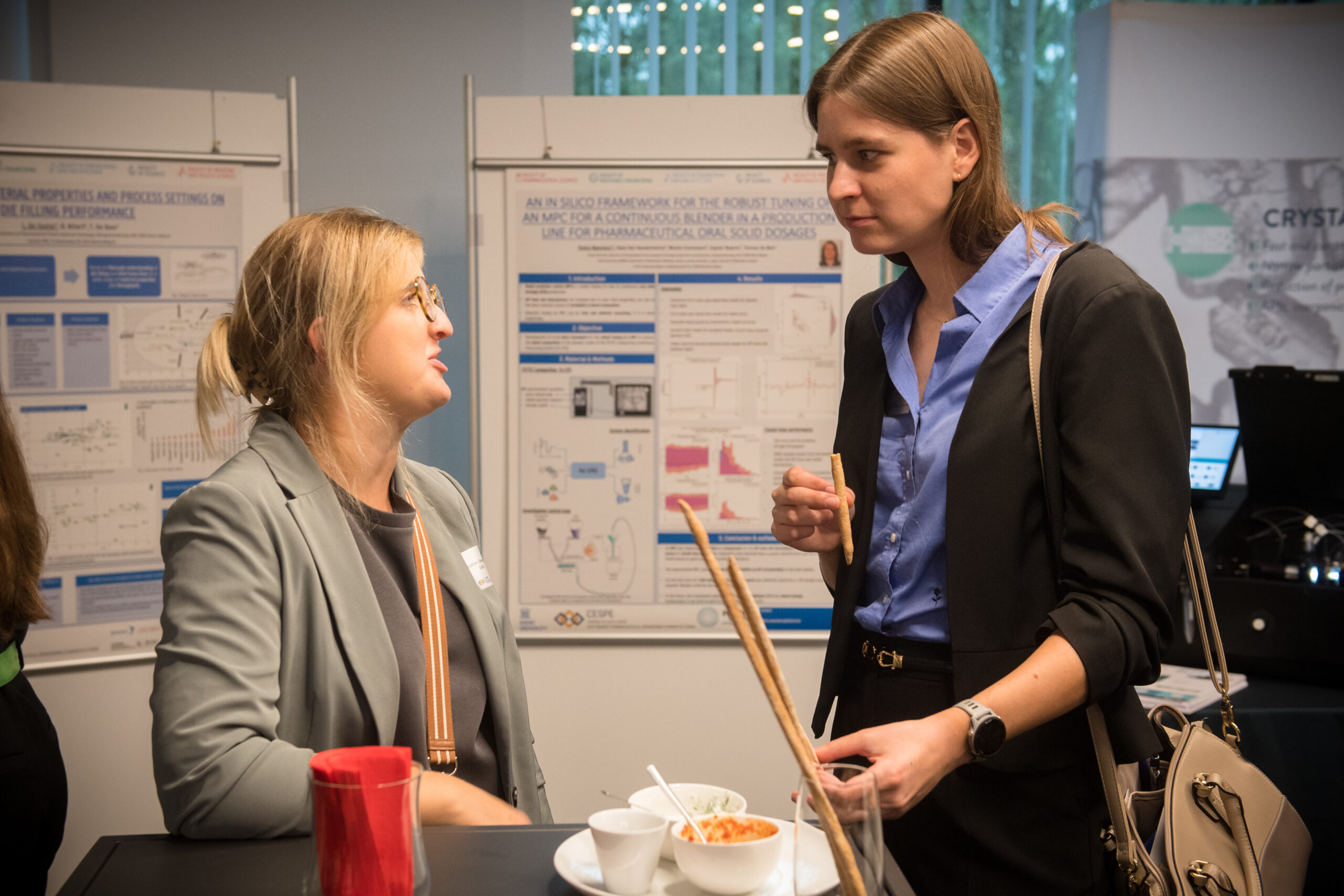

Registration & Welcome

Networking breakfast

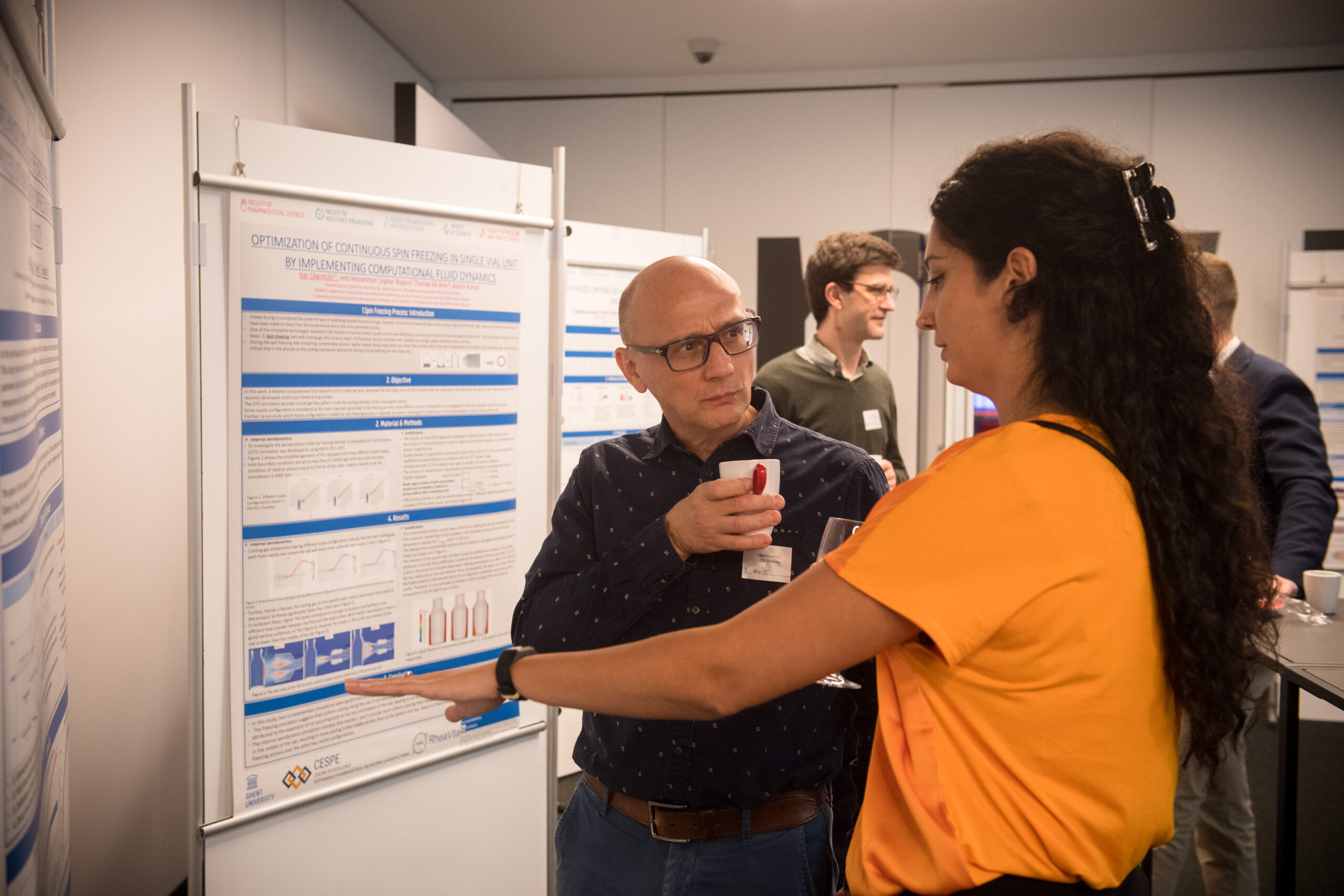

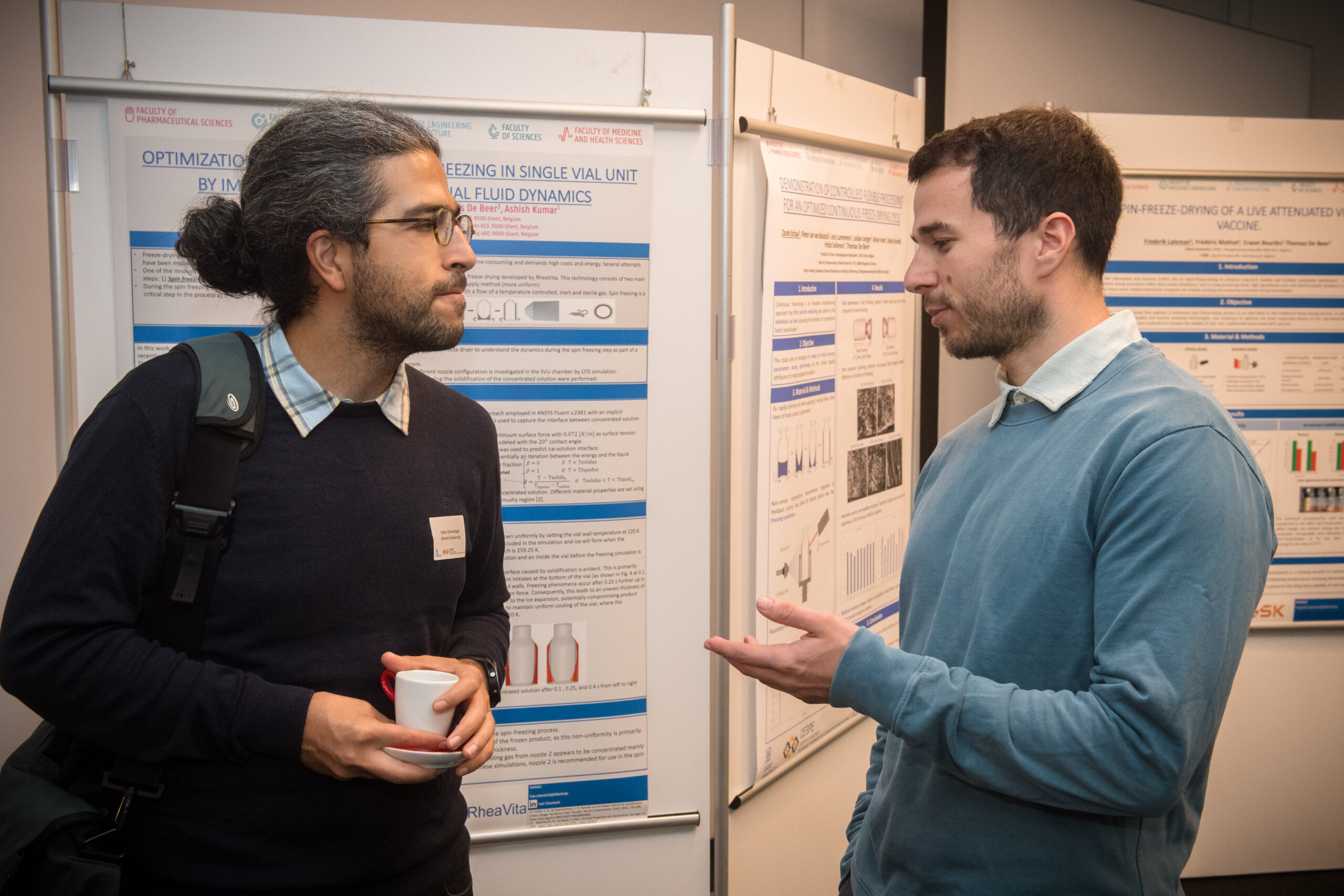

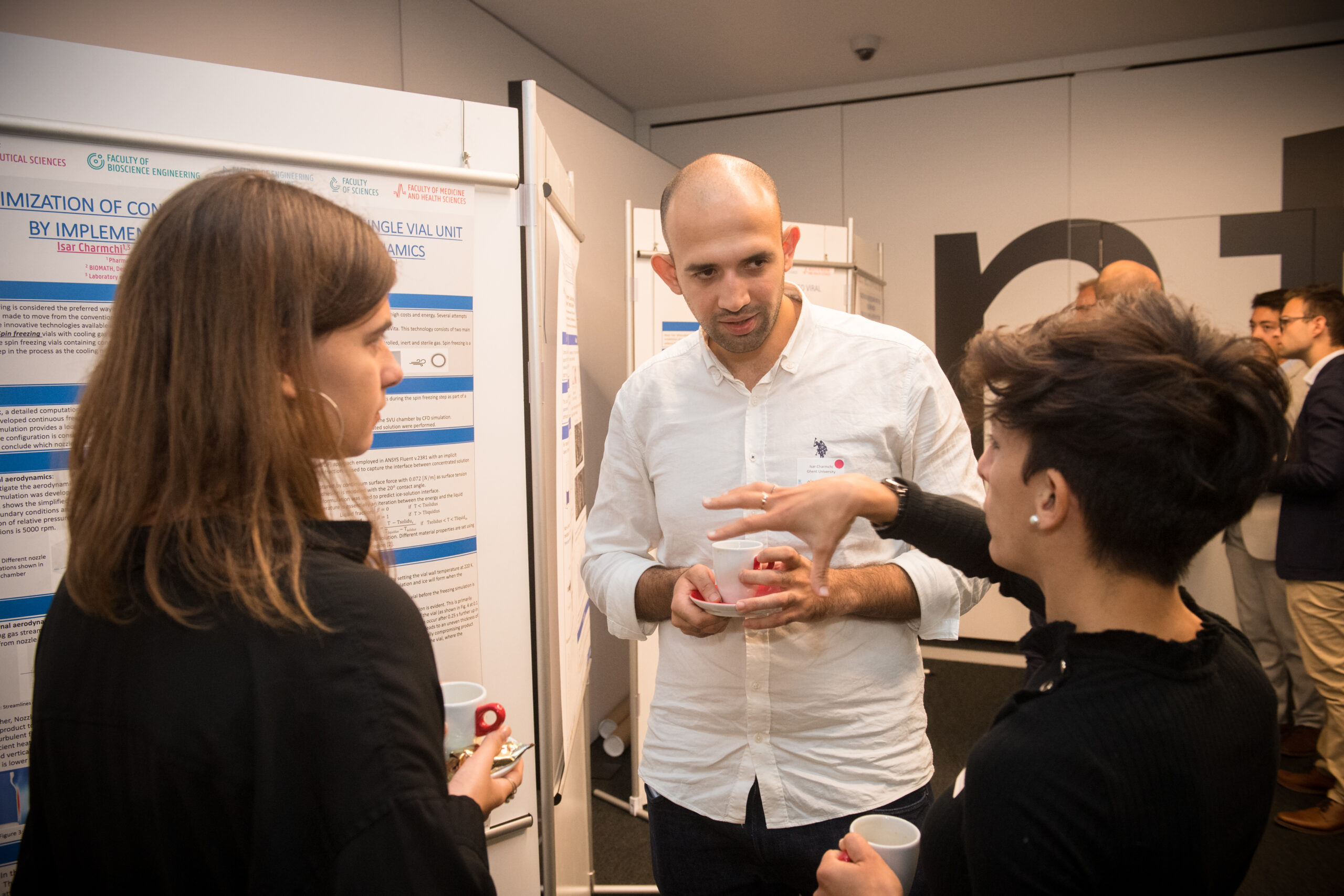

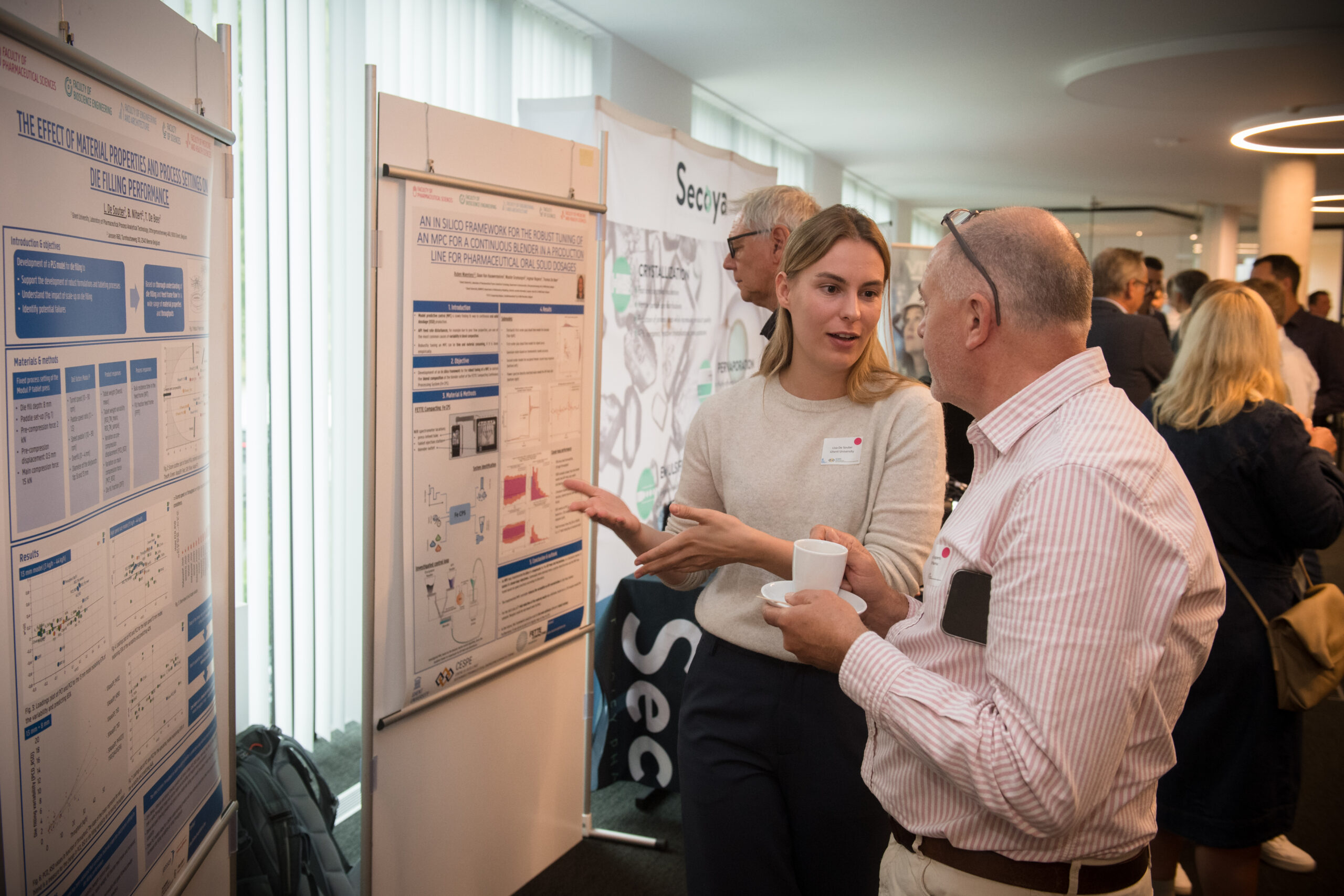

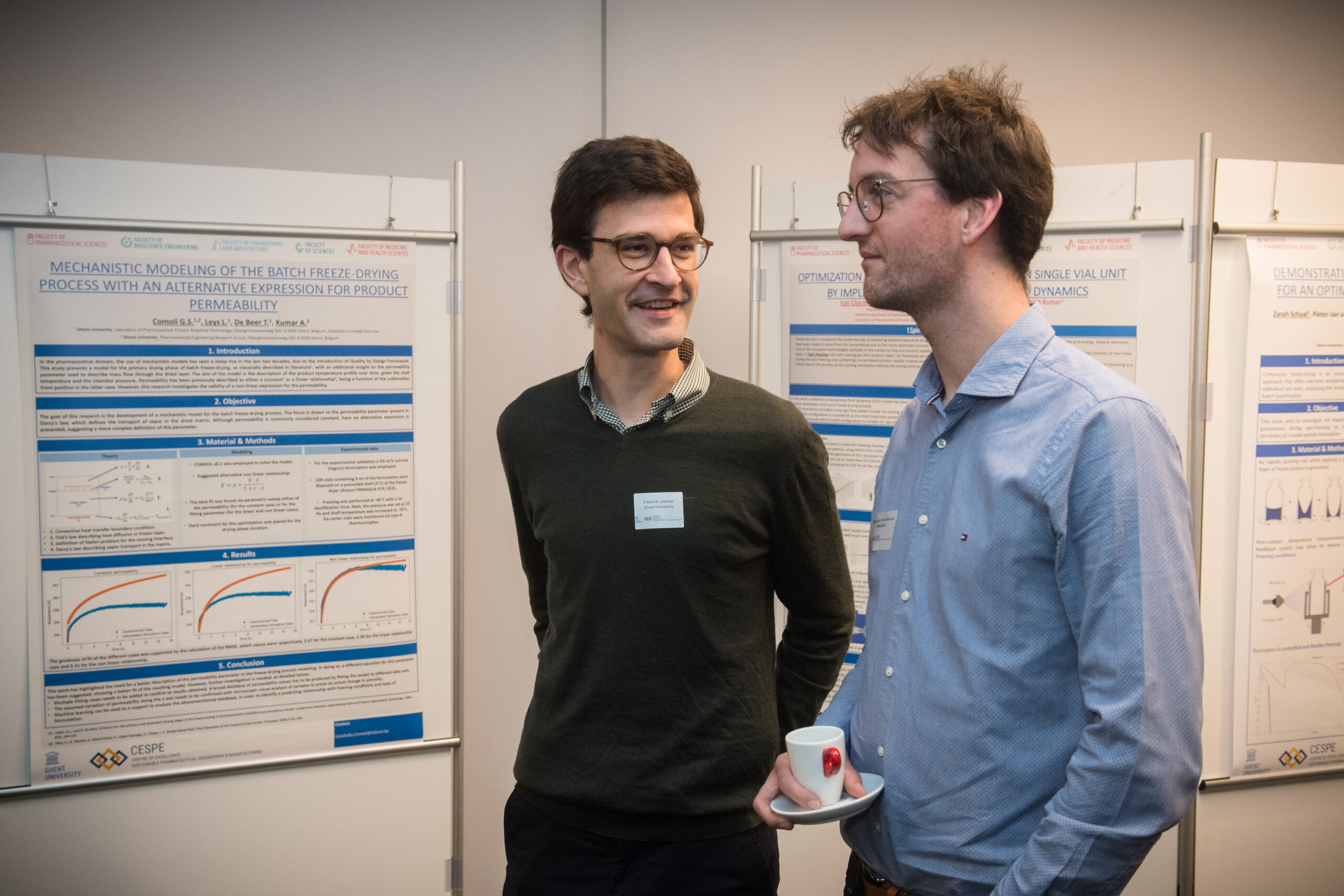

Poster exhibition + booths

09h30 – 09h40

Conference opening

Sofie Bracke, Deputy Mayor of Ghent, responsible for Economy, Port and Sports

09h40 – 10h00

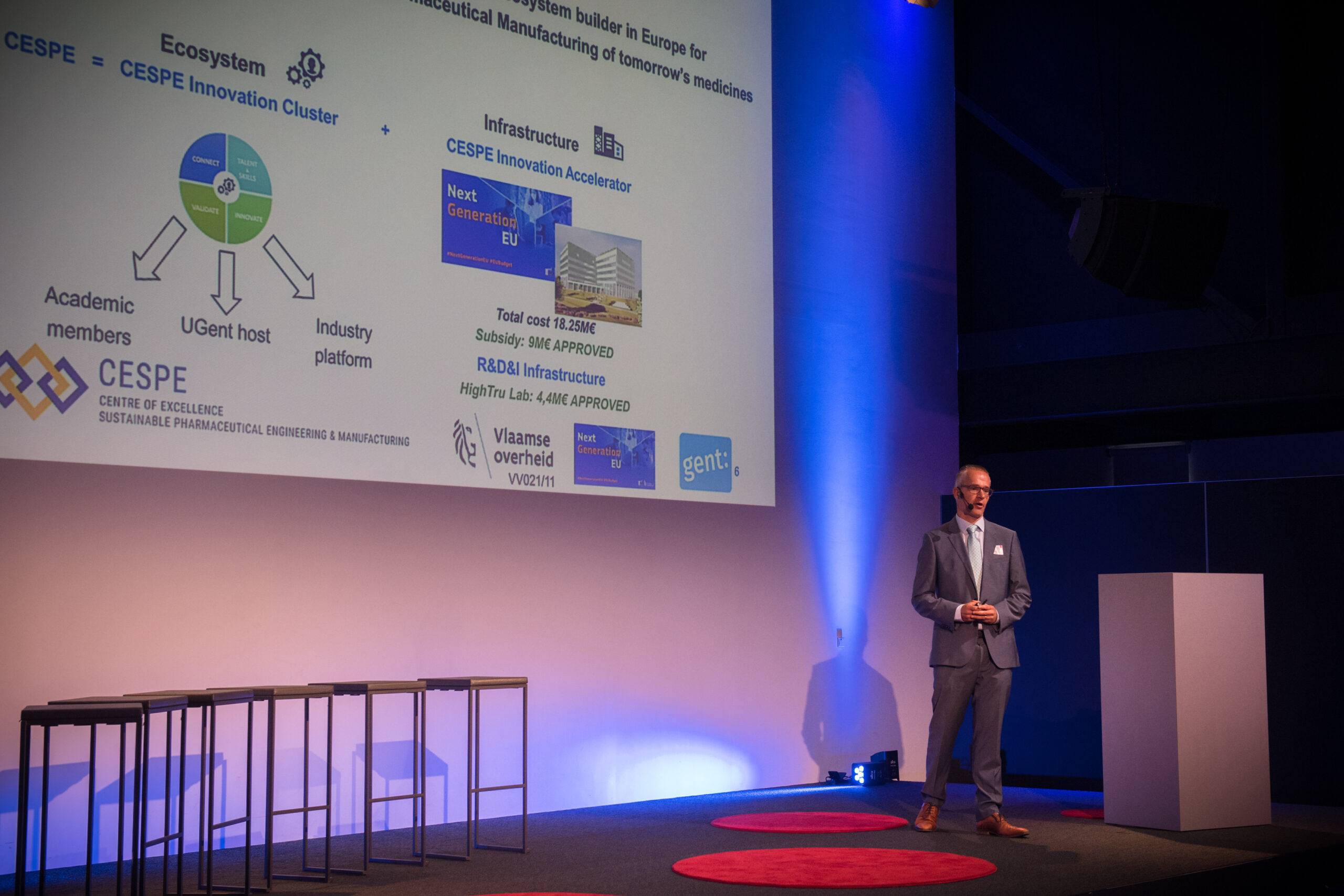

Introduction to CESPE & Update building

Prof. Thomas De Beer, CESPE Director

Dr. Christoph Portier, CESPE General Manager

PART 1:

Perspective from the pharmaceutical and biopharmaceutical Industry

– Goals – State-of-the-art – Bottlenecks –

Delegates from the big pharmaceutical and biopharmaceutical companies will highlight their company’s perspective on the current goals, state-of-the-art and bottlenecks related to their big investments in the transition towards sustainable manufacturing.

10h00 – 10h20

Environmental sustainability in the Small Molecules Active Pharmaceutical Ingredient’s

synthesis: from global policy into action.

Bert Heirman, Program Manager Strategic Sustainability Initiatives – Small Molecules, Janssen Pharmaceutica Geel

&

Bie Lambert, Head of Operations for Janssen Pharmaceutica Geel, Janssen Pharmaceutica Geel

10h20 – 10h40

Journey to a net-zero plasma derived manufacturing facility

Simon Gilleman, Sustainability Manager, Takeda

10h40 – 11h00

Coffee break

Poster exhibition + booths

11h00 – 11h20

(Preliminary) Sustainability in the Biomanufacturing Industry:

Global ambitions – Role of the big pharma – No-brainers – Struggles

David Vertongen, Sr. Technical Design Lead, Pfizer

11h20 – 11h40

Sustainability during Drug Product Manufacturing Development.

Jan-Sebastiaan Uyttersprot, PAT Principal Scientist, UCB Pharma

PART 2:

Contributions from Academic & Industrial stakeholders

– Chemical manufacturing – Biotech manufacturing – Drug Product Manufacturing –

Three consecutive sessions will be held where both academic and industrial stakeholders will showcase how their innovative approaches could play a crucial role in the sustainability advancements in different areas within pharmaceutical and biopharmaceutical manufacturing.

Session 1 – Chemical manufacturing

11h40 – 11h55

Digital technologies reducing the footprint in Pharma, examples from the Industry

Dirk Wollaert, Manager Business Development Pharma USA, Siemens Digital Industries

11h55 – 12h10

Transitioning to a more sustainable API development

Prof. Chris Stevens, Principal Investigator, CESPE

12h10 – 12h25

Towards a better process understanding and intensification by modeling

Prof. Joris Thybaut, Principal Investigator, CESPE

12h25 – 13h55

Networking lunch

Poster exhibition + booths

Session 2 – Biotech manufacturing

13h55 – 14h10

How Sustainability Meets Efficiency in Freeze-Drying

Mathieu Massart, Engineering Manager, RheaVita

14h10 – 14h25

Data, Artificial Intelligence & Analytics for Sustainable (Bio)Pharmaceutical Manufacturing.

Noah Nzuki, ESG Lead EMEA, Cognizant

14h25 – 14h40

Pharmaceutical Freeze-Drying: Innovations for a Smaller Ecological Footprint

Carolin Reinke, Senior Innovation Manager Pharma & Healthcare, GEA

Session 3 – Drug Product manufacturing

14h40 – 14h55

SUSTAIN: SUstainability STrAtegy ImplementatioN, from ESG to the working plant

Christian Post, Senior Process Engineer, VTU

14h55 – 15h10

Use of microfluidics to revolutionize the production of pharmaceuticals

Tim Dieryckx, CEO, Voxdale

15h10 – 15h25

The triple bottom line in healthcare: A holistic sustainability assessment for decision support

Prof. Delphine De Smedt, Principal Investigator, CESPE

15h25 – 15h45

Coffee break

Poster exhibition + booths

PART 3:

Staying ahead of what’s next

– Roundtable discussion – Innovation Café –

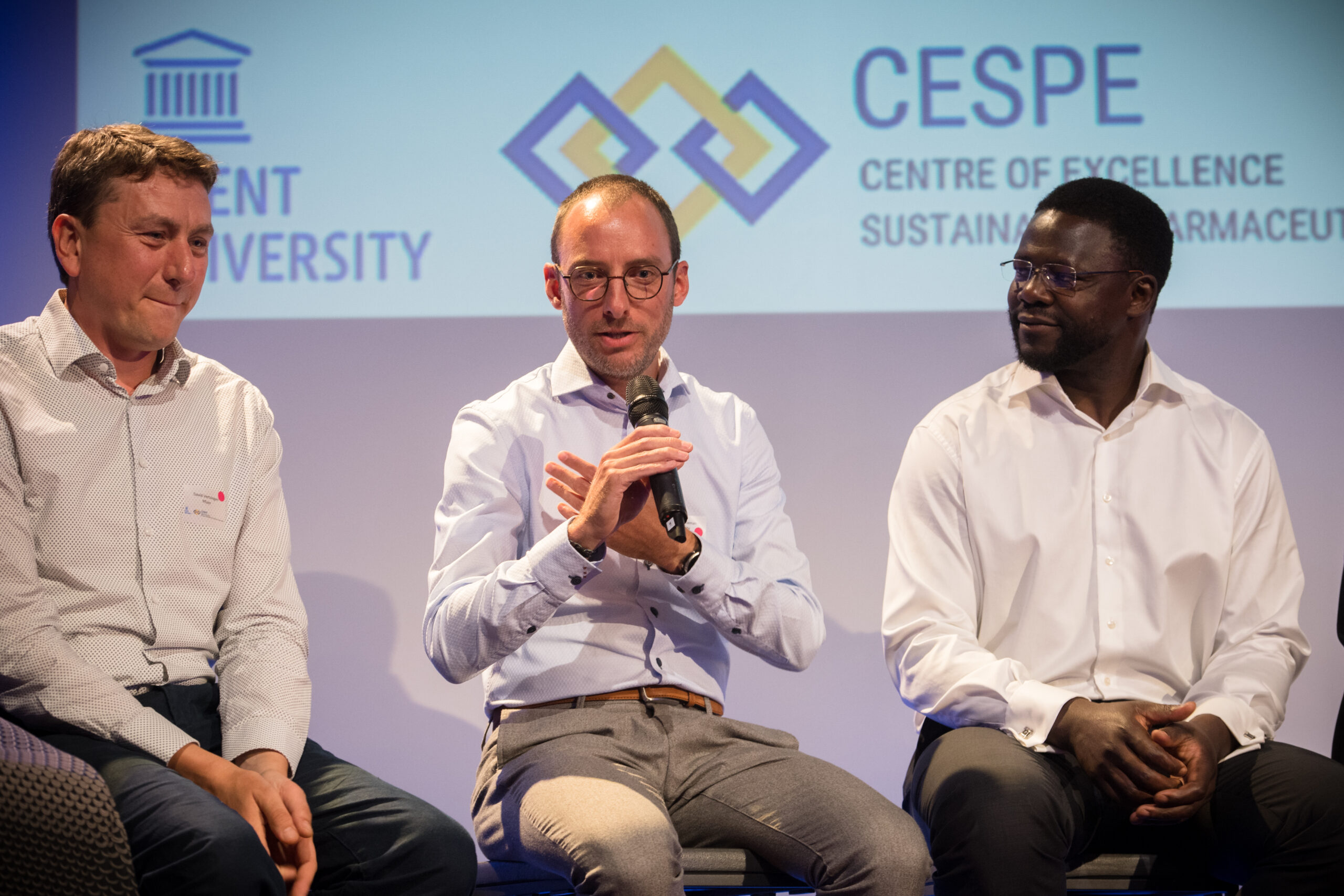

15h45 – 16h30

Roundtable discussion

Representatives from different key stakeholders groups will have an open discussion about the current challenges and innovations facilitating the transition towards sustainable pharmaceutical and biopharmaceutical manufacturing.

Get inspired by the insights of these key opinion leaders from industry, academia and policy makers.

Moderator

Tineke Van Hooland, Founder and CEO, Epic 10

Panel

Talia Flanagan, Head of Product Design and Performance, UCB Pharma

David Vertongen, Sr. Technical Design Lead, Pfizer

Simon Gilleman, Sustainability Manager, Takeda

Noah Nzuki, ESG Lead EMEA, Cognizant

Delphine De Smedt, Principal Investigator, CESPE

Isabelle Francois, Director Innovation, MEDVIA

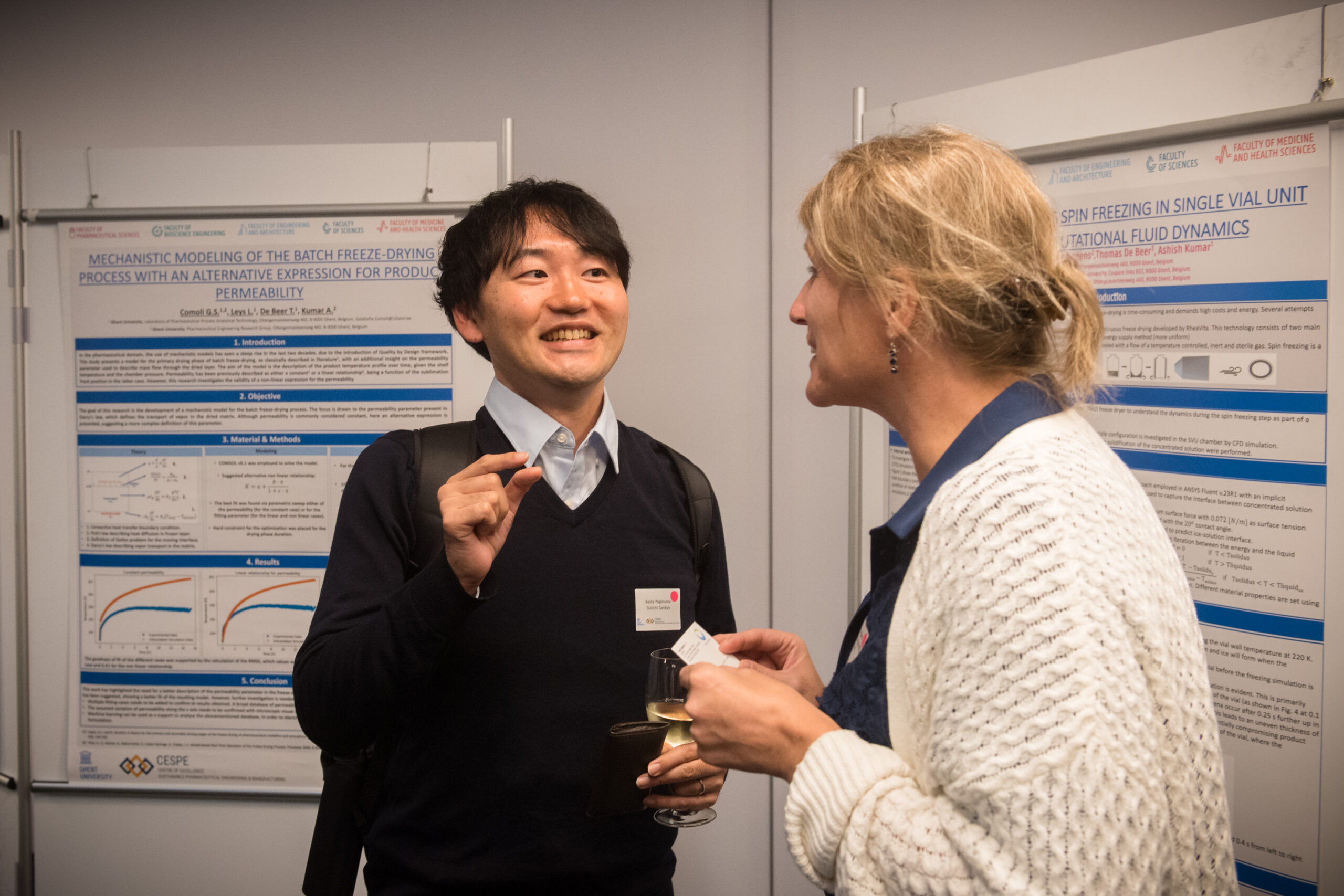

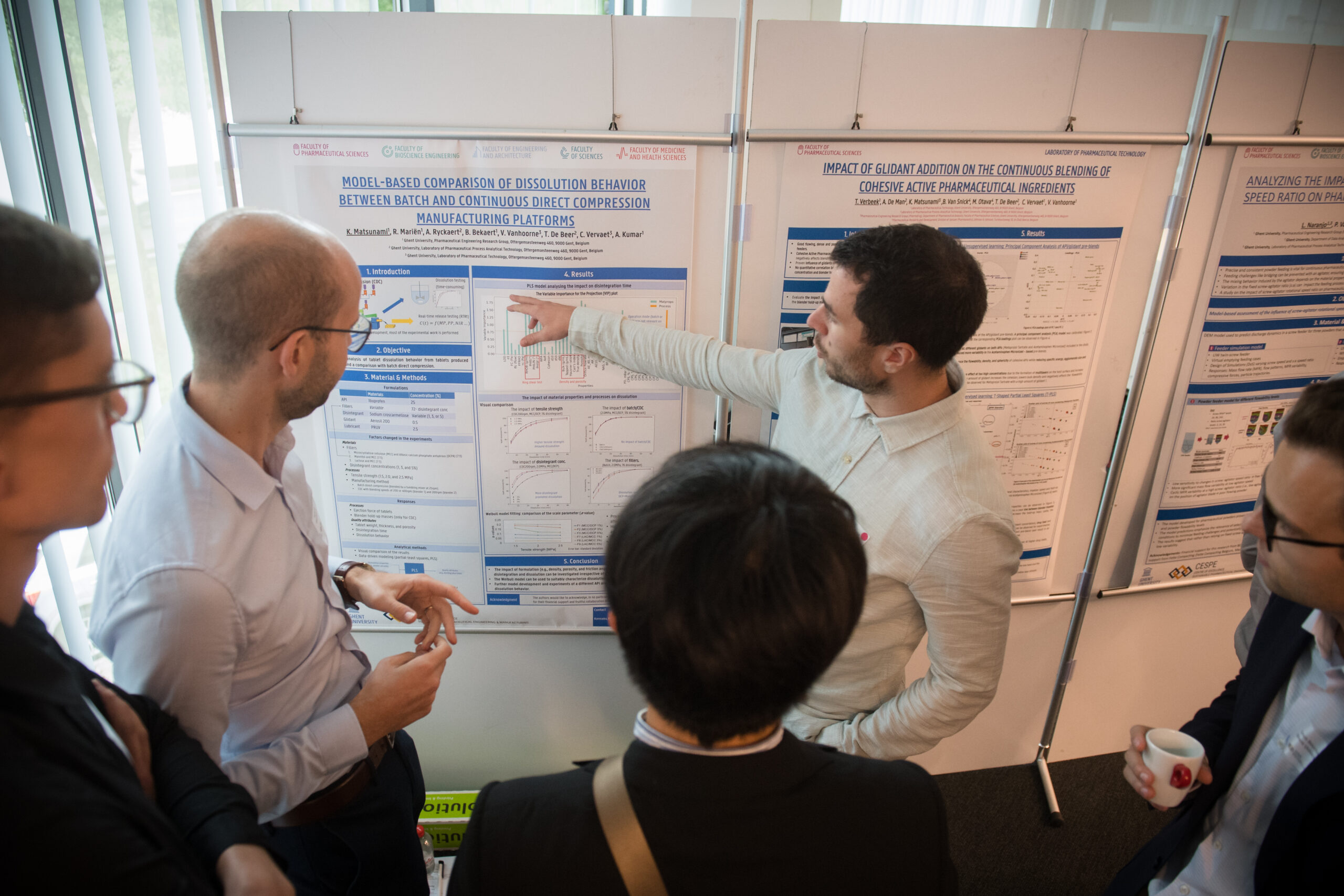

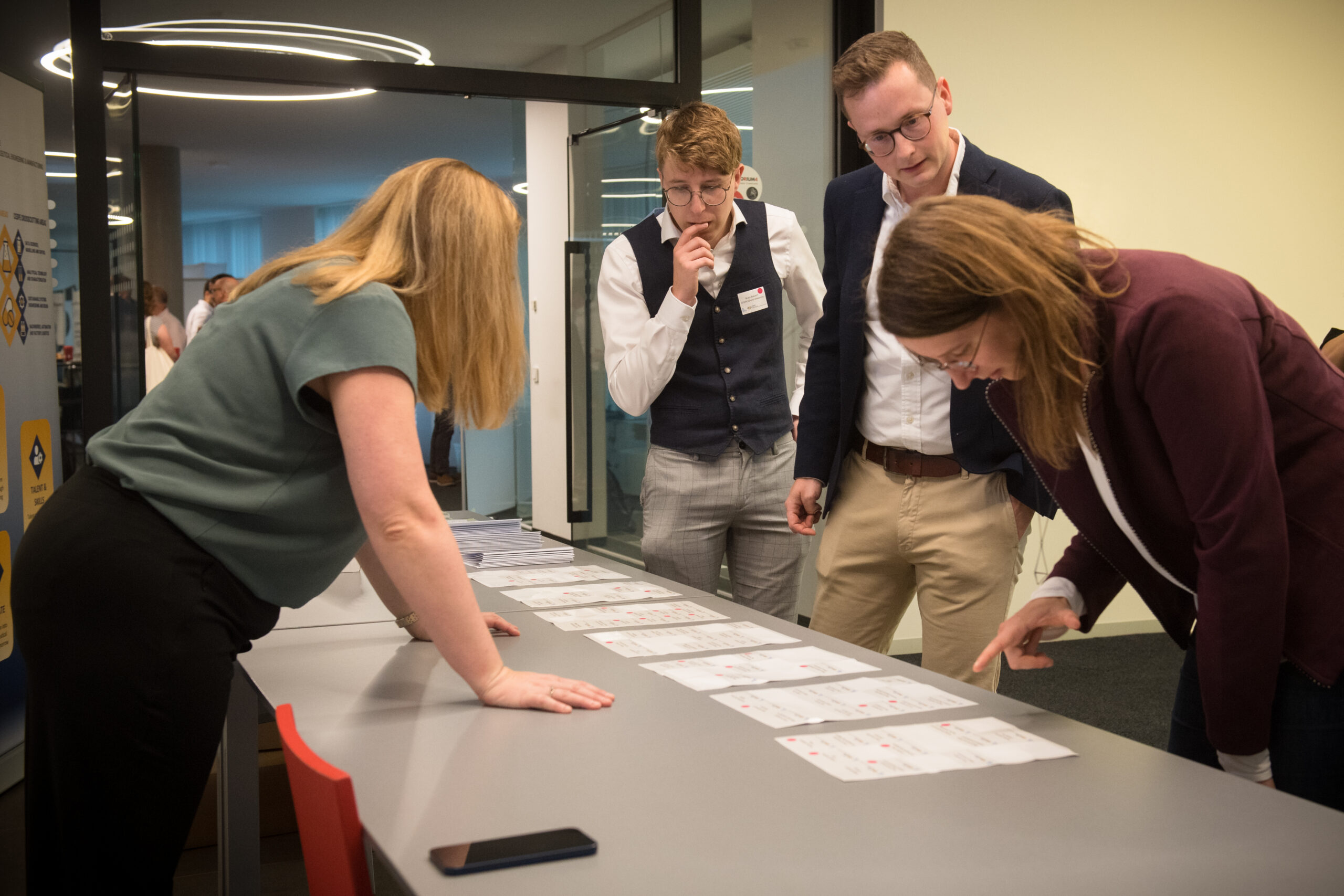

16h30 – 17h20

Innovation Café

The talented people within CESPE will have the chance to pitch their innovative research to a broader audience.

Don’t miss this sneak-peek in the ongoing research within the different CESPE groups and member companies!

Take a look at the submitted abstracts for the Innovation Café.

Closing

17h20 – 17h30

Closing word

Prof. Dieter Deforce, Principal Investigator, CESPE

Networking Reception & Dinner

17h30 – …

Poster exhibition + booths