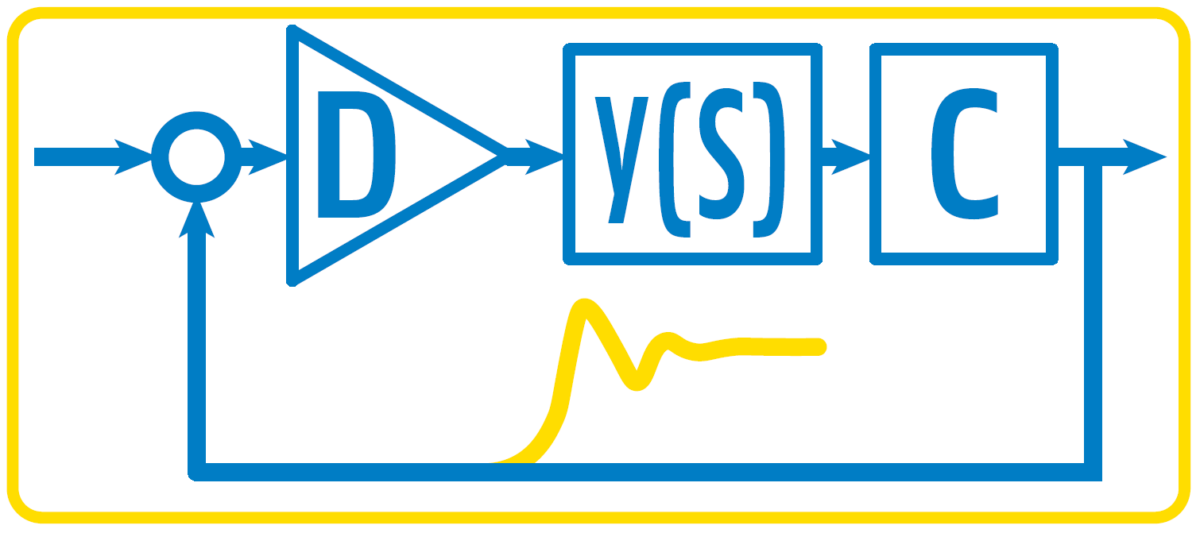

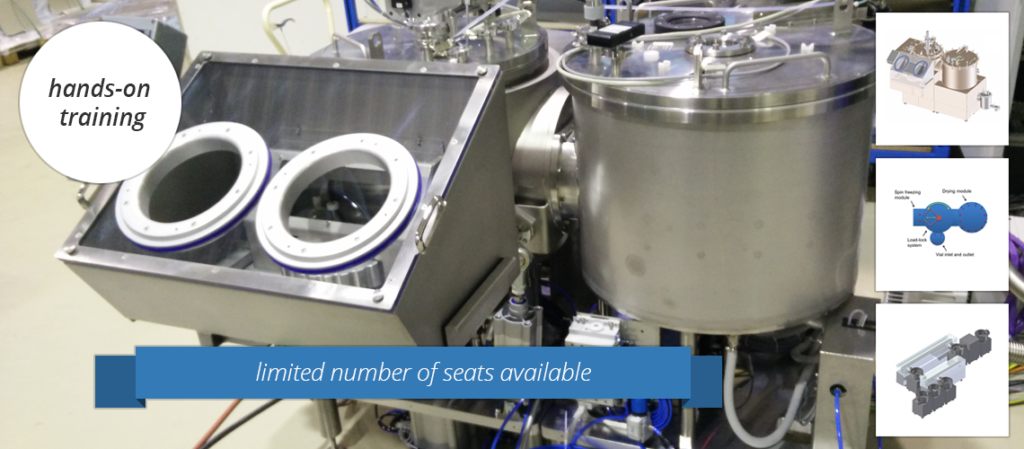

At BIOMATH, we develop and apply mathematical models and methodologies for the analysis and optimization of (bio)processes. The primary focus is on mechanistic models used to support a variety of priority sectors such as pharmaceutical manufacturing technology.

During the last decade, the focus of the group shifted towards a triangle of modelling frameworks, subsequently extending the conventional bio-kinetic models with Computational Fluid Dynamics (CFD) and Population Balance Models (PBM).

- CFD extends the level of spatial description of reactor systems and was felt as a need since systemic models, such as tanks-in-series approach, became limiting.

- PBM was a logical addition since this was the topic of Prof. Nopens’ PhD dissertation. This framework allows to model the dynamics of distributed properties of a population of individuals.

Also, combinations of the frameworks can be used to answer complex problems. In that sense, one of the current strategies of BIOMATH is the development and experimental validation of complex models for process understanding. Such a detailed modeling step can be followed by a model reduction step to create simplified models. In the sense that they are mathematically and computationally easier to solve, more accurate, require less calibration and, therefore, have a higher predictive power as compared to lumped process models. BIOMATH has consequently gained extensive expertise in the fields of computational fluid dynamics, population balance modelling and bio-kinetics.