COURSE OVERVIEW

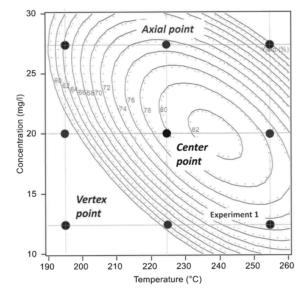

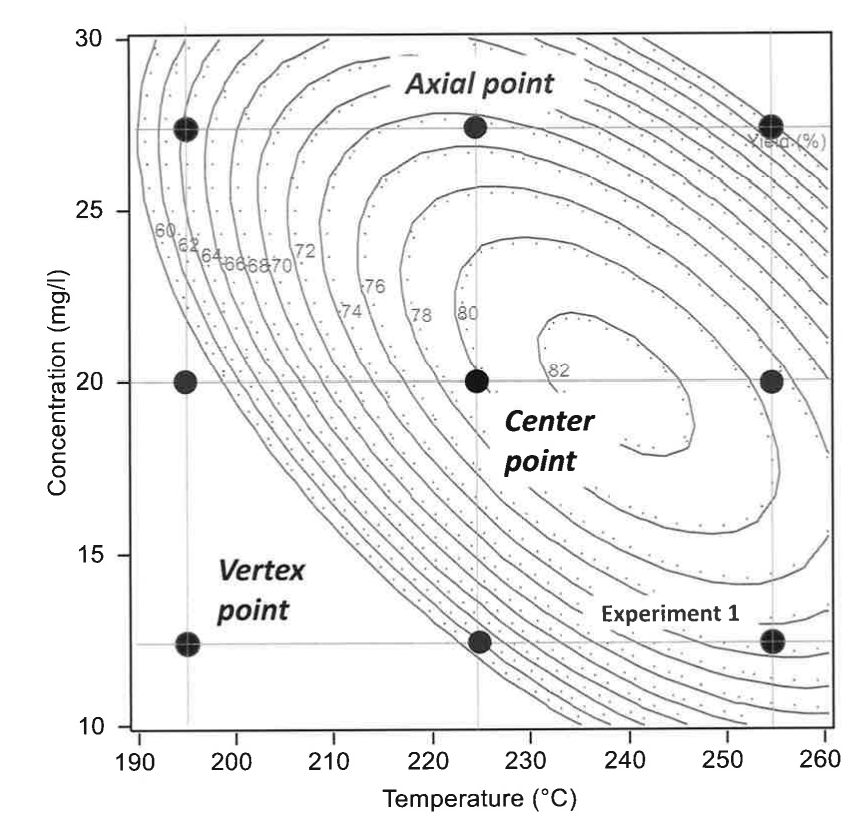

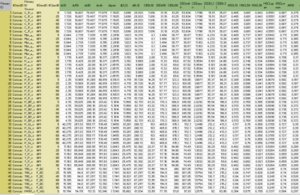

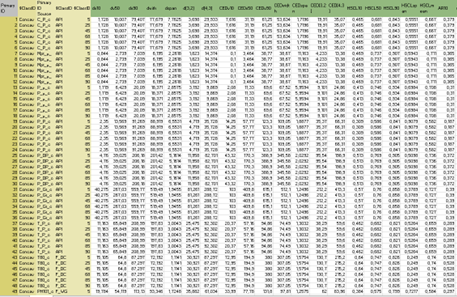

The DOE training is hands-on and designed for individuals who want to actively engage in Experimental Design and gain a better understanding of the statistical analysis of experimental data. The course emphasizes the Optimal Design of Experiments, matching the experimental design to the problem while considering all experimental boundary conditions and constraints. Optimal DOE is computer-aided, meaning experiment runs and regression models are generated by computer algorithms; the software package used is JMP. The topics are illustrated through case studies and examples from industrial R&D, making the training particularly relevant for professionals in that field.

The course is divided into two modules, each lasting one full day. The basic module begins by covering the necessary theory, including basic training in linear multiple regression analysis for analyzing experimental data and establishing statistical process models needed for parameter screening and optimization. Additionally, the JMP software package will be introduced, and simple cases will be reviewed to describe the basic DOE approach. The advanced module covers more complex examples with specific experimental conditions. In each of the case studies, the goal is to improve the performance of a process or product through efficient exploration and optimization.

Target audience

The target audience is professionals or students in chemical, pharmaceutical & healthcare sciences and engineering.

COURSE PROGRAM

A detailed overview of the different modules can be found in the following document.

If you are interested in taking this course, please email sarah.costers@ugent.be or mgadbruy.debruyne@ugent.be.